Chinese Scientists Make Breakthrough in Designing Multicomponent Alloys with exceptional combination of tensile ductility and yield strength

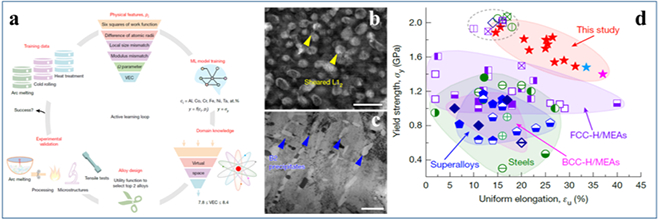

Figure. Domain knowledge-based machine learning model for the discovery of ultra-strong and ductile Fe35Ni29Co21Al12Ta3 multicomponent alloys with dual precipitates (a, b, c), rendering the Fe35Ni29Co21Al12Ta3 alloys with record-high yield strength-uniform elongation combination, surpassing the room-temperature mechanical properties of reported metallic materials (d)

Supported by the National Natural Science Foundation of China (Grant Nos. 52441407, 52431006, 92163201, U23A6013), the research team led by Professors, Jinyu Zhang, Jun Sun and En Ma from Xi’an Jiaotong University has achieved significant advancements in designing the multicomponent alloys with record-high combination of yield strength and large uniform elongation via the domain knowledge-based machine learning method. This study, titled “Machine-learning design of ductile FeNiCoAlTa alloys with high strength”, was published in Nature on June 18, 2025 (https://www.nature.com/articles/s41586-025-09160-2).

High yield strength and tensile ductility are crucial for their engineering applications of metallic materials. However, for all the alloys developed thus far, those possessing good tensile ductility rarely approach 2 GPa yield strength at room temperature. Most of the few that do are mostly ultrastrong steels, but these materials suffer from insufficient work hardening capability during plastic deformation. As a result, the reported uniform elongation in standard uniaxial tensile tests is often attributed to serrated plastic flow, rather than truly uniform elongation. These ultra-strong steels, such as in some maraging steels, have very low uniform elongation (~3.8%). Although the classic second phase strengthening mechanism can effectively enhance the yield strength of alloys, the strengthening levels is often limited by the precipitate fractions (often < 50 vol.%), associated with notably reduced ductility. Thus, designing 2-GPa yield strength MCAs with truly uniform elongation > 10% is a grand challenge.

To address these challenges, a team under the guidance of Prof. Jun Sun at the National Key Laboratory for Mechanical Behavior of Materials, Xi'an Jiaotong University, proposed a new approach to designing ultra-strong-yet-ductile alloys utilizing ultrahigh volume fraction of intermetallic precipitates, i.e., coherent L12 nanoprecipitates and incoherent low modulus-yet-hard deformable B2 microprecipitates. The design idea includes: i) A ultra-high volume fraction of coherent L12 nanoprecipitates with high antiphase boundary energy to increase the strength, ii) A high volume fraction of low modulus incoherent B2 microprecipitates. On the one hand, incoherent interfaces are more effective in hindering dislocation motion to improve the yield strength than coherent interfaces. On the other hand, the introduction of multiple alloying elements reduces the antiphase boundary energy of B2 microprecipitates to increase their plasticity, allowing these B2 particles to act as dislocation storage units and improve work hardening ability. A domain knowledge-based machine learning model was employed to design the compositions of MCAs (Fig. a) via the codoping of the high solubility of lightweight Al and the L12 antiphase boundary energy enhanced element Ta (rather than Ti) to obtain the L12+B2 strengthened Fe35Ni29Co21Al12Ta3 MCA, containing a high fraction of coherent L12 (67 vol.%, Fig. b) and incoherent deformable B2 (15 vol.%, Fig. c) embedded in an FCC matrix. The coherent L12/FCC and incoherent B2/FCC interfaces can strongly interact with dislocations, in terms of dislocation nucleation and dislocation accumulation. In particular, the low modulus B2 microprecipitates can store more dislocation than the (FCC+L12) matrix to enhance the work hardening rates of Fe35Ni29Co21Al12Ta3 MCAs and thus the yield/tensile strength and ductility. As a result, the Fe35Ni29Co21Al12Ta3 MCA shows exceptional combination of tensile ductility and yield strength at room temperature, obviously surpassing the mechanical properties of reported metallic materials. This alloy design strategy, through active learning-guided heavy alloying and extraordinary amounts of precipitates is expected to be applicable to other alloy systems.

Contact Us

National Natural Science Foundation of China

Add: 83 Shuangqing Rd., Haidian District, Beijing, China

Postcode: 100085

Tel: 86-10-62327001

Fax: 86-10-62327004

E-mail: bic@nsfc.gov.cn